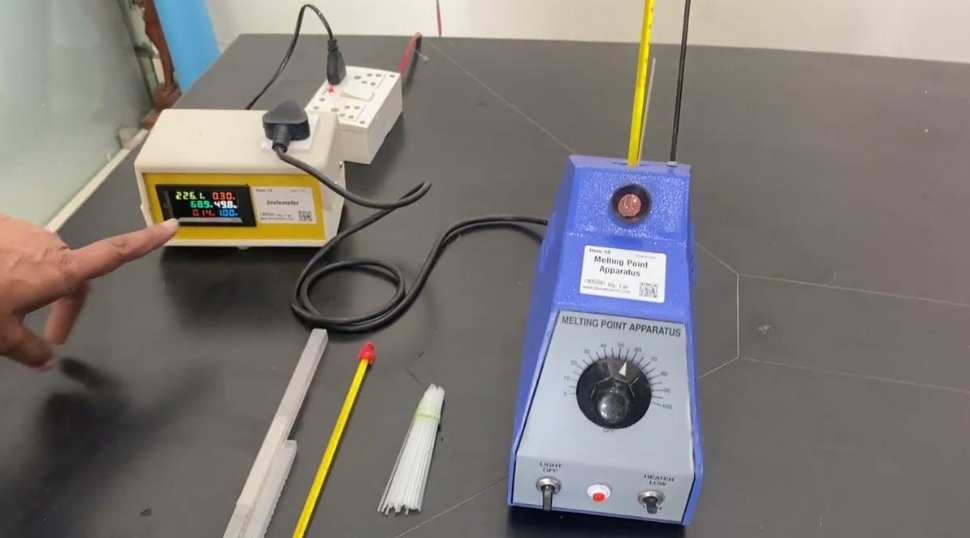

Understanding the Role of a Melting Point Meter in Modern Laboratories

Introduction to Melting Point Measurement

In scientific research and industrial applications, determining the melting point of a substance is a fundamental analysis. A melting point meter is an essential laboratory instrument that provides precise and rapid determination of the temperature at which a solid substance transitions to a liquid state. Accurate melting point measurement is crucial for quality control, purity assessment, and compound identification across various industries.

The evolution from traditional manual methods melting point meter to modern melting point meters has significantly improved accuracy, efficiency, and reproducibility of measurements, making these devices indispensable in laboratories worldwide.

Importance of Accurate Melting Point Determination

The melting point of a substance provides critical information about its chemical properties. Accurate measurement helps in:

- Assessing Purity: Pure compounds exhibit a sharp melting point, while impurities typically cause broadening or depression of the melting range.

- Identifying Compounds: Melting point data assists in confirming the identity of synthesized or unknown compounds.

- Ensuring Quality Control: Industries rely on melting point data to verify product specifications and maintain consistency.

A reliable melting point meter ensures that laboratories can generate consistent, reproducible data with minimal human error.

Features of Modern Melting Point Meters

Modern melting point meters incorporate advanced technology to enhance functionality and ease of use:

- Digital Temperature Display: Accurate, clear readings allow for precise monitoring of melting transitions.

- Automated Detection: Sensors detect the exact melting point without manual observation, reducing subjective errors.

- Rapid Heating and Cooling: Shortens testing time while maintaining accuracy.

- Small Sample Requirement: Minimal material is needed, preserving valuable substances.

- Data Storage and Export: Enables record-keeping and integration with laboratory management systems.

These features make modern melting point meters more efficient and user-friendly compared to conventional capillary methods.

See also: How Tech Is Changing the Face of Journalism

Applications in Various Industries

Melting point meters are widely used across multiple sectors due to their versatility:

- Pharmaceutical Industry: Used for quality control and verification of active pharmaceutical ingredients (APIs).

- Chemical Industry: Helps in identifying synthesized compounds and evaluating purity.

- Food Industry: Certain food additives, fats, and oils require melting point analysis for quality assessment.

- Academic and Research Laboratories: Assists in the study of chemical compounds and material characterization.

- Cosmetics Industry: Ensures that waxes, creams, and other components meet consistency and stability requirements.

By offering precise and reproducible measurements, melting point meters play a crucial role in maintaining product standards and facilitating research.

Advantages Over Traditional Methods

Traditional manual methods of determining melting points often involved visual observation of a substance in a capillary tube under a microscope. Modern melting point meters offer numerous advantages:

- High Accuracy: Automated sensors eliminate subjective reading errors.

- Time Efficiency: Rapid heating and automated detection reduce analysis time.

- Reproducibility: Consistent results ensure comparability between samples and experiments.

- Enhanced Safety: Minimal handling reduces exposure to potentially hazardous compounds.

- Data Management: Digital systems allow recording and exporting of results for documentation purposes.

These advantages make modern melting point meters an essential upgrade for laboratories seeking reliable and efficient measurement tools.

Selecting the Right Melting Point Meter

Choosing the appropriate melting point meter requires careful consideration of laboratory needs:

- Temperature Range and Precision: Ensure the device can handle the expected range of melting points for your samples.

- Sample Capacity: Some instruments allow simultaneous testing of multiple samples.

- Ease of Calibration: Instruments with automated calibration routines maintain accuracy over time.

- User Interface and Software: A simple interface and software connectivity facilitate ease of operation and data management.

- Brand Reliability: Partnering with a trusted supplier ensures consistent product quality, support, and longevity.

Selecting a high-quality instrument from a reputable manufacturer helps laboratories achieve accurate and reproducible results with minimal operational challenges.

Maintenance and Longevity

Proper maintenance extends the life and performance of a melting point meter:

- Regular Cleaning: Keep sample holders, heating blocks, and sensors free from residue to ensure accurate readings.

- Calibration Checks: Periodic verification using standard reference substances maintains measurement reliability.

- Software Updates: Ensure firmware is up-to-date for optimal functionality and compatibility with laboratory systems.

- Safe Storage: Protect the instrument from dust, moisture, and mechanical damage.

Following these practices maximizes instrument longevity and guarantees consistent performance over time.

Innovations in Melting Point Technology

Manufacturers continue to enhance melting point meters with innovative features:

- High-Throughput Analysis: Instruments capable of analyzing multiple samples simultaneously improve laboratory efficiency.

- Remote Monitoring: Some models allow remote operation and data review, enabling flexible workflow management.

- Compact Designs: Space-saving instruments optimize laboratory bench space without compromising functionality.

- Advanced Sensors: Improved temperature sensors enhance accuracy and detection sensitivity for challenging samples.

These innovations demonstrate the commitment of manufacturers to meet evolving laboratory and industrial needs.

Cost and Investment Considerations

Investing in a high-quality melting point meter involves evaluating several factors:

- Initial Cost vs. Long-Term Benefits: Higher upfront investment is often offset by reduced labor, improved accuracy, and durability.

- Support and Warranty: Access to reliable technical support and comprehensive warranty ensures minimal downtime.

- Scalability: Consider instruments that allow upgrades or expansions to accommodate future laboratory needs.

- Supplier Reputation: Reliable suppliers provide consistent product quality and expert guidance.

Careful evaluation ensures laboratories obtain a device that provides excellent value and supports consistent, reliable measurements.

Conclusion

A melting point meter is a vital instrument for laboratories seeking precise, efficient, and reproducible measurement of melting points. Its advantages over traditional manual methods, combined with advanced features such as automated detection, digital displays, and data integration, make it indispensable across research, pharmaceutical, chemical, and food industries.

Selecting a high-quality melting point meter from a reputable manufacturer ensures accuracy, reliability, and long-term performance. Proper maintenance, calibration, and adherence to manufacturer guidelines further enhance the instrument’s lifespan and ensure dependable results.

For laboratories aiming to maintain product quality, streamline workflows, and improve measurement reliability, investing in a melting point meter is a practical and worthwhile decision.